- +91 9130015631

- prajapatifdrypl@reddifmail.com

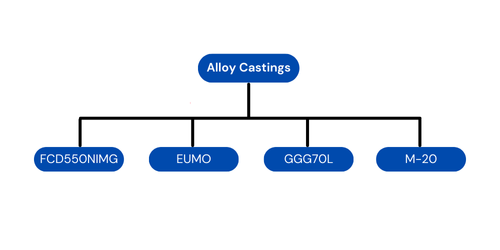

Used in critical engine components, gearboxes, and brake systems where high strength and wear resistance are essential.

Ideal for parts subjected to high stress and abrasion, such as pumps, valves, and hydraulic components.

Employed in aerospace components where high strength-to-weight ratios and resistance to extreme conditions are crucial.

Utilized in parts for mining and construction machinery that require robust performance and durability.

F - II Block, Plot No. 14, Telco Material Gate Road, MIDC Pimpri, Bhosari, Pune-411018, Maharashtra, India

9822768944, 9130013531, 9130015631

prajapatifdrypl@reddifmail.com